Visual Inspection Training (VT)

Elevate your inspection skills with visual inspection training from NDT-CGI

Beyond the naked eye: Empowering visual inspection with technology

- Corrosion: VT excels at detecting signs of corrosion on various materials, helping to ensure their structural integrity.

- Misalignment: Improper alignment of components can be readily identified through visual inspection.

- Physical damage: Scratches, dents, and other surface imperfections are easily detectable using VT.

- Cracks: VT plays a vital role in identifying cracks on the surface of materials, preventing potential failures.

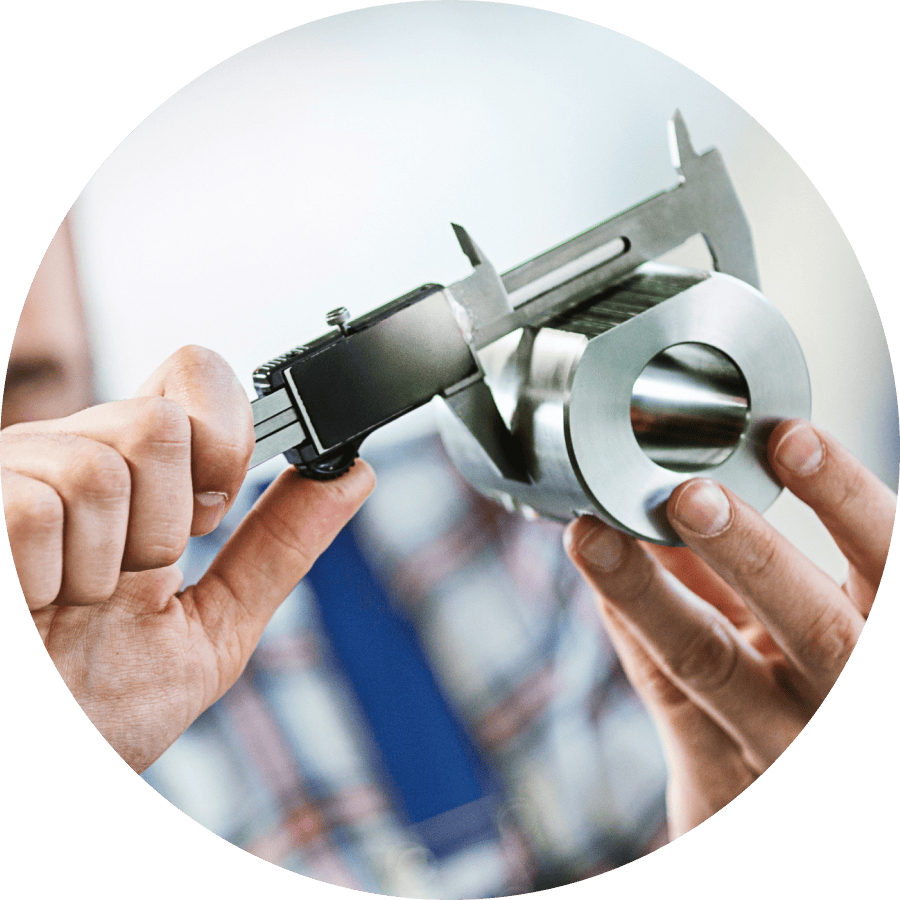

Tools for an effective visual inspection testing

- Magnifying glasses: For a closer look at fine details and potential flaws

- Mirrors: To access and inspect hard-to-reach areas

- Borescopes: For visual examination of internal cavities and pipelines

- Computer-assisted viewing systems: For capturing, enhancing, and recording visual data for detailed analysis

Advantages and limitations of visual inspection

A rigorous NDT visual inspection training program empowers inspectors to maximize the benefits of VT while effectively addressing its constraints.

Advantages

Cost-effectiveness:

VT is one of the most economical NDT methods, requiring minimal investment in equipment or consumables.

Enhanced portability:

VT equipment is often portable or nonexistent, making inspections feasible in various environments without the need for bulky setups.

Rapid results:

VT delivers immediate results, allowing for quick decision-making during the quality control process.

Accessibility for newcomers:

VT requires minimal specialized skills compared to other NDT methods. However, visual inspection training can significantly enhance an inspector's ability to identify defects and ensure consistent, reliable results.

Minimal preparation needs:

VT often requires minimal preparation of the test object, making it a time-saving approach.

Limitations

Limited scope:

VT is inherently restricted to inspecting surfaces that are directly visible to the inspector. Hidden defects or flaws below the surface cannot be detected using VT.

Size sensitivity:

Generally, VT is most effective at detecting larger surface defects. Smaller imperfections might be more difficult to identify or even missed entirely during an inspection.

Interpretation challenges:

Distinguishing certain defects like scratches from cracks can be challenging based on visual observation alone. Training and experience play a crucial role in accurate VT interpretation.

Other Services

Explore our comprehensive suite of NDT training services

We offer a complete suite of services for program establishment, audits, and examinations.