NDT Radiography Training (RT)

Elevate your inspection capabilities with expert NDT radiography training

Peering beyond the surface: The power of radiographic inspection

- Petrochemical industry: RT plays a vital role in inspecting pressure vessels, valves, and other equipment for defects that could compromise safety and operation.

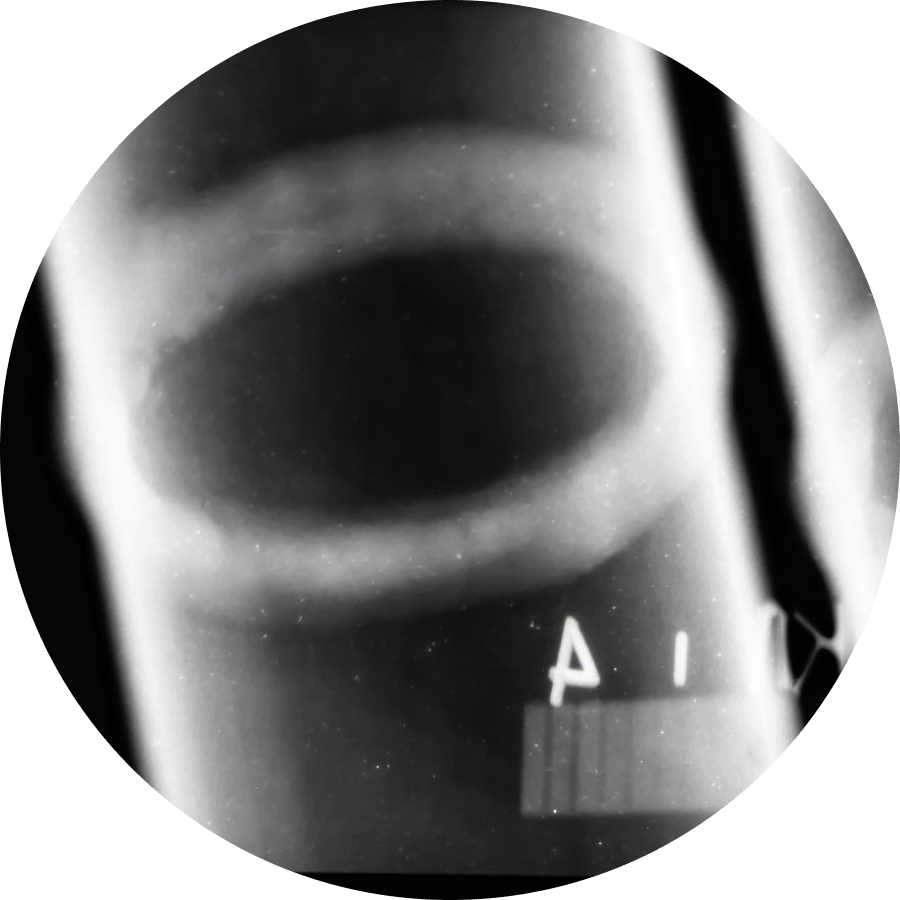

- Weld inspection: RT is a valuable tool for inspecting weld repairs, verifying the quality of the weld and identifying any internal imperfections.

A look at radiography techniques

- Conventional radiography: This established technique uses X-ray film to capture internal images of the test object. While reliable, it requires film processing and can be time-consuming compared to digital methods.

- Digital radiographic testing (DRT): DRT offers a digital alternative to conventional film-based RT. It uses digital detectors to capture images electronically, providing faster results and improved image manipulation capabilities.

- Real-time radiography (RTR): This method allows for real-time visualization of the internal structure during the inspection, enabling immediate decision-making.

- Computed radiography (CR): CR utilizes storage phosphor imaging plates to capture X-ray images. These plates can be reused after being read electronically, offering a cost-effective alternative to film.

- Direct radiography (DR): DR employs digital flat-panel detectors to capture X-ray images. This method offers high-resolution images and near real-time results.

Advantages and limitations of radiography

Undergoing NDT radiography training equips you with the expertise necessary to employ RT effectively and allows you to learn its capabilities and constraints in upholding and enhancing quality standards when performing material testing.

Advantages

Minimal surface preparation:

RT's non-intrusive nature means that almost no surface preparation is needed, streamlining the inspection process.

Material versatility:

RT’s ability to penetrate various materials, including metals, composites, and plastics, makes it incredibly versatile.

Comprehensive component inspection:

RT can inspect components in their assembled state, providing a holistic understanding of structural integrity.

Limitations

Safety concerns with ionizing radiation:

The use of hazardous ionizing radiation necessitates stringent safety measures, including establishing a safety perimeter around the inspection area.

High equipment costs:

The technology and equipment required for RT can be a considerable investment.

Requirement for two-sided access:

Effective inspection demands access to both sides of the test object, which may not always be feasible.

Inspection time:

Compared to some other NDT methods, RT can be more time-consuming, requiring careful planning and execution.

Other Services

Explore our comprehensive suite of NDT training services

We offer a complete suite of services for program establishment, audits, and examinations.