Magnetic Particle Testing Training (MT)

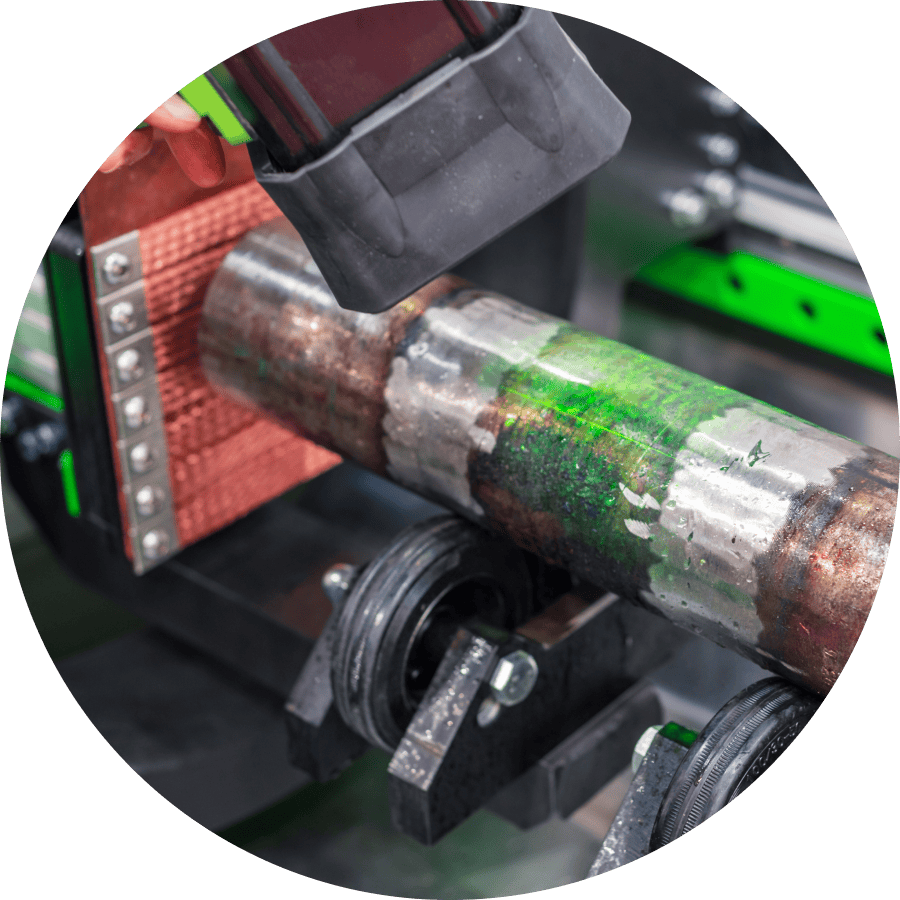

Enhancing surface integrity inspection for ferromagnetic metals

Understanding magnetic particle testing

Enhanced visibility for critical inspections

Our magnetic particle testing training course is tailored for your learning needs

- 1. Principles of Magnets and Magnetic Fields

- Theory of magnetic fields

- Earth’s magnetic field

- Magnetic fields around magnetized materials

- 2. Theory of Magnetism

- Magnetic poles

- Law of magnetism

- Materials influenced by magnetic fields

- Ferromagnetic

- Paramagnetic

- Diamagnetic (magnetic characteristics of non-ferrous materials)

- 3. Magnetic Particle Testing Terminology

- 4. Characteristics of Magnetic Fields

- Bar magnet

- Ring magnet

- 5. Effect of Discontinuities of Materials

- Surface cracks

- Scratches

- Subsurface defects

- 6. Magnetization by Means of Electric Current

- Circular field

- Field around a straight conductor

- Right-hand rule

- Field in parts through which current flow

- Long, solid, cylindrical, regular parts

- Irregularly shaped parts

- Tubular parts

- Parts containing machined holes, slots, etc.

- Methods of inducing current flow in part

- Contact plates

- Prods

- Discontinuities commonly discovered by circular fields

- Longitudinal field

- Field produced by current flow in a coil

- Field direction in a current-carrying coil

- Field strength in a current-carrying coil

- Discontinuities commonly discovered by longitudinal fields

- Advantages of longitudinal magnetization

- Disadvantages of longitudinal magnetization

- 7. Selecting the Proper Method of Magnetization

- Alloy, shape, and condition of part

- Type of magnetizing current

- Direction of magnetic field

- Sequence of operations

- Value of flux density

- 8. Inspection Materials

- Wet particles

- Dry particles

- 9. Principles of Demagnetization

- Residual magnetism

- Reasons for requiring demagnetization

- Longitudinal and circular residual fields

- Basic principles of demagnetization

- Retentivity and coercive force

- Methods of demagnetization

- 10. Magnetic Particle Testing Equipment

- Equipment-selection considerations

- Type of magnetizing current

- Location and nature of test

- Test materials used

- Purpose of test

- Area inspected

- Manual inspection equipment

- Medium- and heavy-duty equipment

- Stationary equipment

- Mechanized inspection equipment

- Semiautomatic inspection equipment

- Single-purpose semiautomatic equipment

- Multipurpose semiautomatic equipment

- Fully automatic equipment

- 11. Types of Discontinuities Detected by Magnetic Particle Testing

- Inclusions

- Blowholes

- Porosity

- Flakes

- Cracks

- Pipes

- Laminations

- Laps

- Forging bursts

- Voids

- Indications of porosity

- 12. Magnetic Particle Test Indications and Interpretation

- Nonrelevant indications

- Indications of nonmetallic inclusions

- Indications of surface seams

- Indications of cracks

- Indications of laminations

- Indications of laps

- Indications of bursts and flakes

Advantages and limitations of magnetic particle testing

While nondestructive testing magnetic particle inspection offers a multitude of advantages, it's essential to understand its limitations to ensure it's the right testing method for your specific application. MT training equips inspectors with the knowledge and skills to leverage the strengths of MT while mitigating its limitations.

Advantages

Speed and efficiency:

Magnetic particle inspections are renowned for their quick turnaround times. This makes them ideal for situations demanding rapid testing and minimal downtime.

Immediate results:

Unlike some NDT methods, MT results are readily visible on the surface of the test piece. This allows inspectors to identify defects quickly and efficiently.

Minimal surface preparation:

MT doesn't require extensive pre-cleaning of the test surface, saving time and resources during the inspection process. Post-cleaning is often not necessary either.

High sensitivity:

MT is great at detecting even fine cracks and other shallow surface defects, making it a valuable tool for ensuring the integrity of critical components.

Versatility:

MT can detect both surface and near-surface defects, expanding its range of applications.

Limitations

Material dependence:

A key limitation of MT is its restriction to ferromagnetic materials such as iron and steel. Non-ferromagnetic materials like aluminum or composites cannot be inspected using this method.

Surface visibility:

MT can only detect defects that break the surface of the material or lie very close to it. Deeper subsurface flaws might go undetected.

Skill dependence:

The effectiveness of MT inspections relies heavily on the skill and experience of the operator. Proper magnetic particle testing training is crucial for accurate defect identification and interpretation of test results.

Limited through-paint inspection:

While MT can sometimes penetrate thin layers of paint, it's generally less effective for inspecting heavily painted or coated surfaces.

Other Services

Explore our comprehensive suite of NDT training services

We offer a complete suite of services for program establishment, audits, and examinations.