R&D NDT

Nondestructive testing training to drive innovation in R&D teams

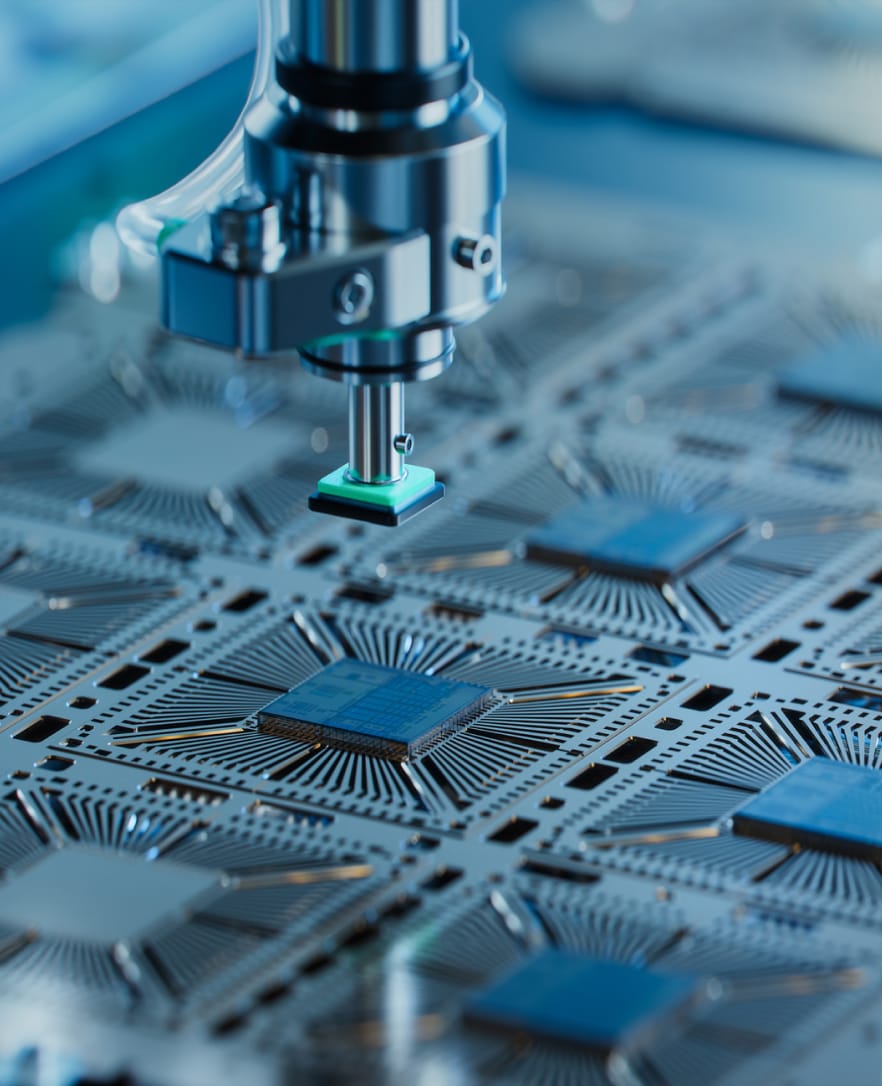

The relentless pursuit of innovation in R&D relies heavily on the integrity and performance of materials used in novel designs and prototypes. Nondestructive testing (NDT) plays a critical role in this process, offering a suite of methods to assess the internal structure and condition of materials without causing damage so as to limit the costs of R&D. NDT for research and development goes beyond traditional applications, requiring a deep understanding of emerging materials and advanced inspection techniques.

R&D NDT training equips professionals with the cutting-edge skills and knowledge to navigate the complexities of research projects. This specialized training covers advanced NDT methods such as microfocus X-ray computed tomography (micro-CT) and phased array ultrasonic testing (PAUT), enabling the detection of even the most minute flaws in intricate prototypes and research materials. Understanding the capabilities and limitations of these techniques allows R&D teams to optimize their inspection strategies, ensuring the quality and reliability of their projects.

Benefits of empowering R&D teams with advanced NDT inspection capabilities

R&D NDT training offers a multitude of benefits for researchers and developers. Here are just a few key advantages:

- Early flaw detection: Traditional inspection methods might miss critical flaws in novel materials or intricate prototypes. R&D NDT training equips professionals with the expertise to utilize advanced techniques that can detect even the most minute defects at the earliest stages of development.

- Material characterization: Beyond flaw detection, R&D NDT empowers a deeper understanding of material properties. Advanced techniques such as micro-CT can reveal internal structures, porosity, and other characteristics and flaws that may be masked by destructive testing techniques.

- Improved design integrity: By providing valuable insights into the internal condition of materials, R&D NDT allows researchers to identify potential design weaknesses early on. This iterative process of inspection and design refinement leads to the creation of robust and reliable prototypes.

- Enhanced safety and reliability: Early detection of flaws during R&D ensures the safety and reliability of prototypes and future products. R&D NDT training empowers researchers to develop a proactive inspection strategy.

- Streamlined communication: A common language of NDT facilitates seamless communication between research teams, engineers, and manufacturing personnel. R&D NDT training equips everyone involved with the understanding and interpretation of inspection results, fostering collaboration and accelerating the innovation process.

Other Industries we serve